Spesnes ICS Easy Start

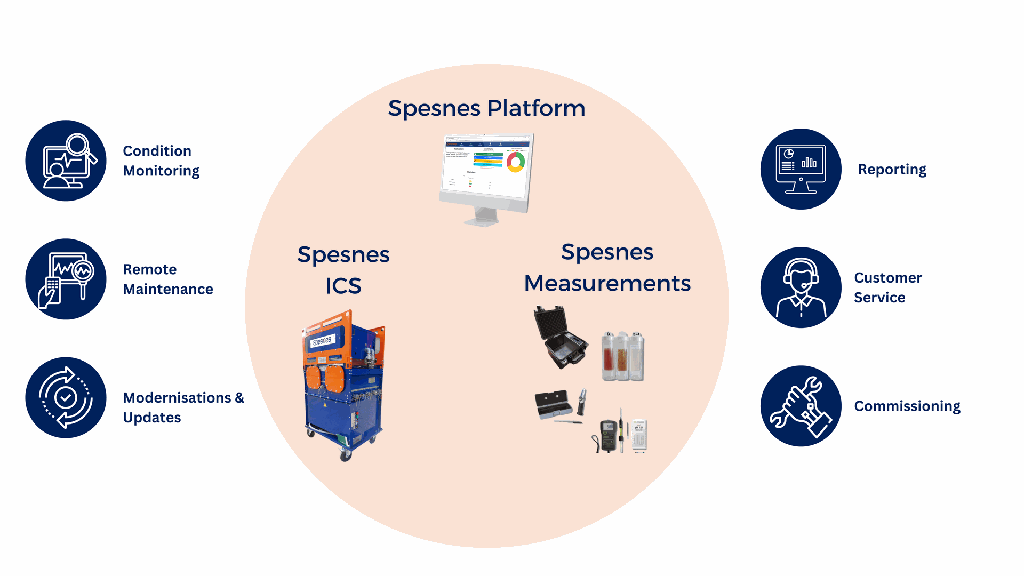

Spesnes ICS: The Complete Solution for Cutting Fluid Management

Spesnes ICS is the perfect solution for cutting fluid management, simultaneously saving the environment, improving workplace safety, and boosting your productivity.

Thanks to its comprehensive service and extensive automation, you save time, money, and resources while ensuring that your cutting fluids always operate at optimal levels.

Easy Start - A Simple and Hassle-Free Package

As the name suggests, the Easy Start package is truly easy. It includes the entire ICS service installed and delivered, including equipment, software, condition monitoring, maintenance, and user training.

After the three-month trial period, you will likely want to continue the contract, but if you’re not satisfied, you can simply end it. Risk-free and, most importantly, easy.

Start Risk-Free Today!

Only €1,740 includes a three-month trial period with installation. No hidden costs. The offer is valid in mainland Finland, excluding the Lapland region. After the trial period, you can decide whether to continue using the system or return the equipment to us.

After placing your order, we will contact you to arrange the installation date.

Delivery time: 1 week to 2 months from order. After your order, we will reach out to you to schedule the installation day.

Spesnes ICS

Multiply the safe and economical lifespan of your cutting fluids

Data-Driven Real-Time Maintenance

The service includes, at no extra cost, the following:

- Spesnes ICS Device:

- Measures all essential values in real time, such as concentration and pH

- Prevents major spoilage factors, such as pH drop.

- Enables effective control of bacteria and other microbes

- Removes harmful particles down to micron-level precision

- Unprecedentedly efficient in removing leak oils.

- Automates concentration and fluid level management with ultra-high accuracy around the clock

- And much more

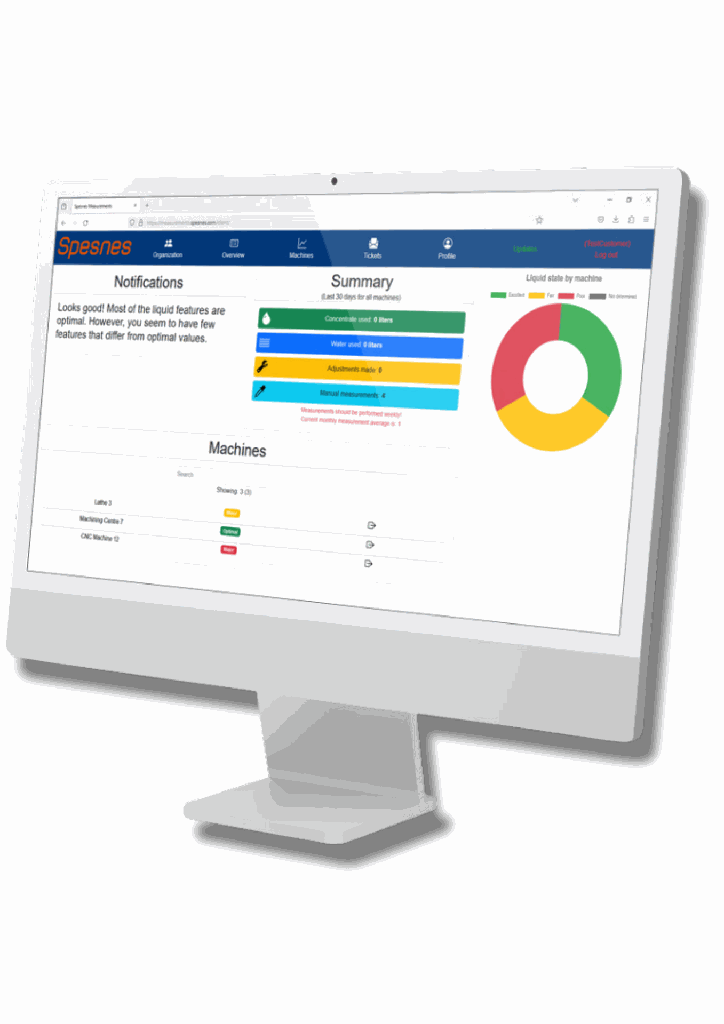

- Spesnes Platform:

- Visualizes fluid condition in real time.

- Raportoi tulokset helposti luettavaksi

- Sends alerts when necessary, so you can focus on essential tasks.

- Documents data for further use, such as occupational health and ESG reporting.

- Spesnes Service:

- Continuous condition monitoring for your cutting fluids and ICS devices.

- Huollot laitteille älykkäiden moduuliratkaisujen avulla

- Software and hardware updates.

- Repairs in case of device failure or replacement if needed.

- Filters and other consumables.

In short, its operation is based on real-time, data-driven optimization of fluid quality. In practice, this means numerous fluid parameters are measured every few seconds — such as concentration, pH, droplet size, conductivity, redox potential, and more. Real-time monitoring is essential because changes in fluids often happen very quickly once they begin. Conversely, this also means that when we detect a shift in the wrong direction, it can still be corrected.

And deviations are corrected. The service includes a dedicated device that handles measurements, adjustments, cleaning, and more automatically — and alerts if abnormalities occur. Our condition monitoring detects issues in both the fluids and the equipment, and we respond quickly. Over 99% of deviations are corrected before they are even manually noticed. Naturally, we also ensure key parameters like concentration and fluid levels remain in the optimal range.

The foundation includes excellent and comprehensive filtration — typically 1–10 microns — plus efficient tramp oil removal to keep the basics in order.

In other words, when the fluids are thoroughly maintained, they function as they should and their lifespan is optimized. For customers, it’s easy — we handle most of the work via the device. Graphs and summaries are automatically generated for each machine and are available when needed.

It’s excellent for both. The modular design allows us to scale capacity as needed.

We have strong references from both 1,000-liter individual machines and 50,000-liter central systems.

When it comes to water-miscible fluids — yes, it’s absolutely suitable! The device, software, and services are modular, allowing us to tailor capacity and features to meet our customers’ specific needs. The system has already been successfully used with dozens of different types of cutting fluids.

The Spesnes ICS service is tank-specific. During development, we also tested portable devices that could be moved between machines. However, we quickly realized that real-time measurement, analysis, adjustment, and cleaning are so critical that moving the device compromised results significantly.

Great question!

It’s important to understand that the device is just one part of the ICS solution. The system acts like a highly efficient worker for your factory — just like a robot. In addition to the “new worker,” you get continuously improving software and several services, most importantly ongoing condition monitoring for your fluids and devices. We also take care of all device maintenance, software updates, consumables like filters, and more. In short: total lifecycle cost management.

This means that unlike traditional investments, Spesnes ICS gets better over time as updates roll out to devices, software, and services. Acquiring the solution is also incredibly easy, as we’ve planned the whole package — including lifecycle needs — for you. And perhaps most importantly: you know exactly what it will cost — no surprise maintenance bills or missing software updates.

There are also financial benefits: capital is freed up for core business activities, costs are tax-deductible immediately, and it’s not uncommon for needs to evolve over time — our service contracts are easy to expand or scale down.

In short: because it’s easy, risk-free, and most of all, sensible.

You only need to ensure there’s a water outlet for a 19 mm inner-diameter hose and a standard 16 A / 30 mA protected SUKO power outlet near the fluid tank.

Full installation requirements are available at spesnes.com/terms

The device is only the size of half a EURO pallet. It can move and rotate on its own wheels, for example, to allow side-access filter replacement.

The floor area needed is about 60 × 80 cm. The height is usually 133 cm, except for high-capacity central system models or units with UV modules, which are 40–80 cm taller.

We connect the device to the fluid tank using three hoses to ensure good circulation. If needed, we also set up a continuous and safe fluid flow between the upper and lower tanks. The device is connected to a water line and a suction hose to a sealed drum or container. The unit includes its own pump for concentrates and automatically mixes them internally.

Yes, it is! We have successfully used the device in cast iron machining. The device, software, and services are modular, meaning capacity and features can be tailored to customer needs — including cast iron operations.