Boost Your Production

Improve Workplace Safety

Reduce Environmental Emissions

Modernize your metalworking fluid system easily and risk-free

Data-driven predictive maintenance for your cutting fluids

Significantly

More Efficient

Production

Properly Functioning Cutting Fluid is Essential for Efficient, High-Quality, and Reliable Production. At the Same Time, the Fluids Require Continuous and Comprehensive Care to Perform Well.

We take care of your fluids so your production won’t stop, and your quality won’t suffer.

Significantly

improved

Workplace Safety

According to the Finnish Institute of Occupational Health, microbes and impurities in cutting fluids are among the biggest occupational safety challenges in machine shops.

We ensure your fluids remain in good condition, so they don't smell or cause unnecessary issues.

80 % Less

Hazardous Waste

and CO2 Emissions

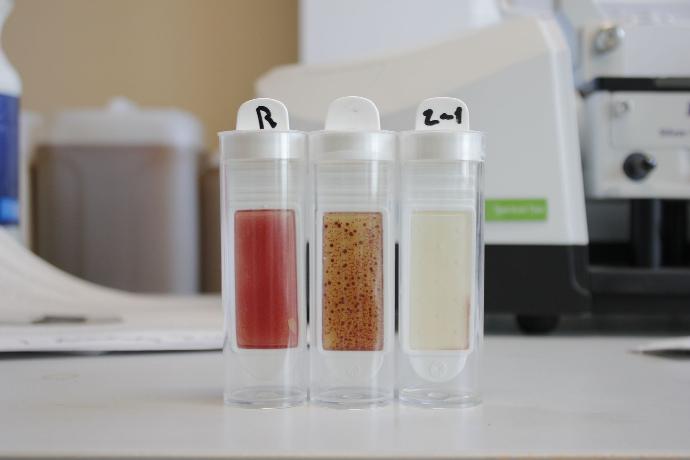

Cutting fluid waste is hazardous and a significant source of carbon dioxide emissions. When properly maintained, the safe lifespan of these fluids can extend up to 10 years.

We Make Maintenance Easy for You with Our Smart Innovations.

Extremely Easy Maintenance Service

INCLUDES AUTONOMOUS ICS SYSTEM INSTALLED.

Or read more about our services

"The machining fluid was deemed ready for replacement according to the manufacturer's tests, and the occupational health doctor advised us to solve our odor problems.

We installed the Spesnes system, and everything is back to normal without replacing the fluid.”

2,000-Liter

Machining Center

Spesnes ICS

A Major Finnish Publicly Listed Company – More Details Available Upon Request

"Spesnes has brought significantly more reliability and peace of mind to our central fluid system.

Maintenance time has been significantly reduced, fluid properties are precisely controlled, and the excellent customer and condition monitoring service ensures fluids perform optimally around the clock."

50,000 litre central system

Spesnes ICS

"The Spesnes system has tripled the lifespan of our grinding fluids.

Technical and environmental issues have decreased along with costs. We are satisfied."

8,000 litre central system

Spesnes ICS

"Spesnes Measurements and its integrated Platform software have improved the management of cutting fluids, reduced the need for supervisory oversight, and made regular documentation easier.

Measurement history is clearly displayed in the Platform, for example, to support occupational safety inspections or production engineering needs.

The visual guidance clearly motivates machinists to maintain their cutting fluids, while also giving meaning to the results — both motivating and educating staff on fluid maintenance.

I recommend it!"

Multiple Machines with Hundreds of Liters Each

Spesnes Measurements